The Nuclear AMRC works with companies through targeted R&D projects to overcome their manufacturing problems, and develop new technical capabilities to compete on cost, quality and delivery.

Our resources and capabilities have been determined by our industry partners, with the aim of helping suppliers reduce cost, improve quality, reduce lead time and cycle time, and reduce risk in manufacturing. You can access our capabilities through company-led commercial R&D projects to meet your specific business needs. Or you can work with other companies and organisations to tackle common challenges through collaborative R&D programmes supported by third-party funding, or company-funded joint industry projects.

We have developed extensive capabilities and expertise in five core R&D areas:

- Machining technologies

- Welding & materials

- Simulation & verification

- Manufacturing engineering

- Controls & instrumentation

Our large-scale R&D capabilities are based at the Advanced Manufacturing Park in South Yorkshire. Our research factory is based around a 5,000 sq m open-plan workshop, designed for working on production-scale technology demonstrators with over £35 million worth of state-of-the-art manufacturing equipment. Many of our machining centres and welding cells feature unique capabilities, or are the largest or most powerful of their kind available for independent industrial research anywhere in the world.

Our engineers have proven experience of working with companies in long-term collaborations to significantly reduce costs and lead times. We have also completed hundreds of shorter projects with a host of companies to investigate new processes, resolve current process problems, and tackle large-scale manufacturing challenges in a variety of sectors.

For full technical details of our equipment and R&D capabilities, download the Nuclear AMRC capability directory (12 MB pdf).

To find out more, contact David Stoddart, head of group.

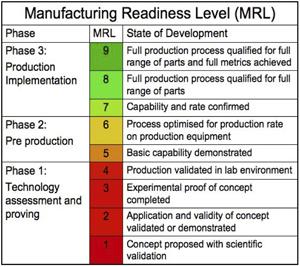

Our research spans the challenging middle stages of the Manufacturing Readiness Level (MRL) scale, taking new manufacturing technologies and processes from proof of concept towards production readiness.

Our research spans the challenging middle stages of the Manufacturing Readiness Level (MRL) scale, taking new manufacturing technologies and processes from proof of concept towards production readiness.